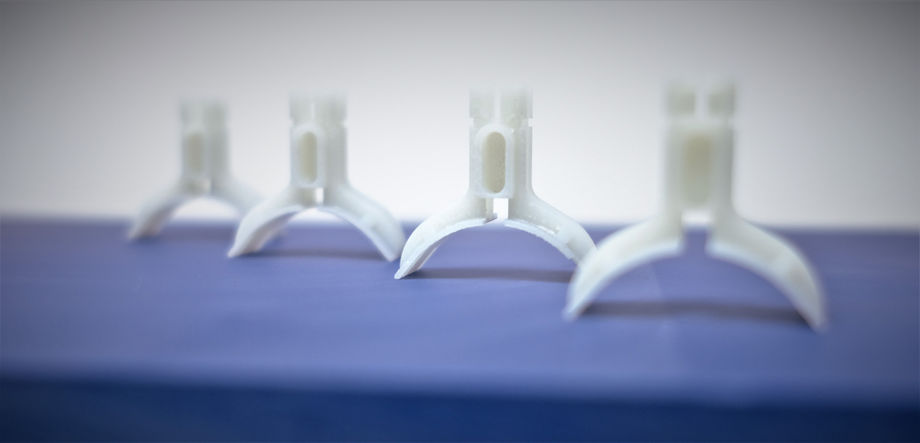

Stereolithography (SLA)

The SLA process builds accurate parts using thin layers and intricate support structures. A laser which generates a small intense beam of ultraviolet (UV) energy is moved by the machine’s optical scanning system across a vat of photosensitive liquid polymer, building your part layer by layer. As the UV beam comes in contact with the polymer, it solidifies to create your finished part.

Stereolithography parts have great surface finish and tight tolerances, the materials used are high performance photo-polymers engineered to serve as functional prototypes, tools & JIGS with fine features.

After printing, all SLA parts can be further finished using various methods of painting, sanding, or sandblasting to produce the premium quality parts needed for the project.

In our factor we currently have 7 production grade SLA machines:

3D Systems - 4X Viper Si2.

Raplas - 700HD+.

Stratasys - Neo450e, Neo450s

Effective maximal building volume: 700mm x 700mm x 420mm.

We process the following materials on our SLA systems: